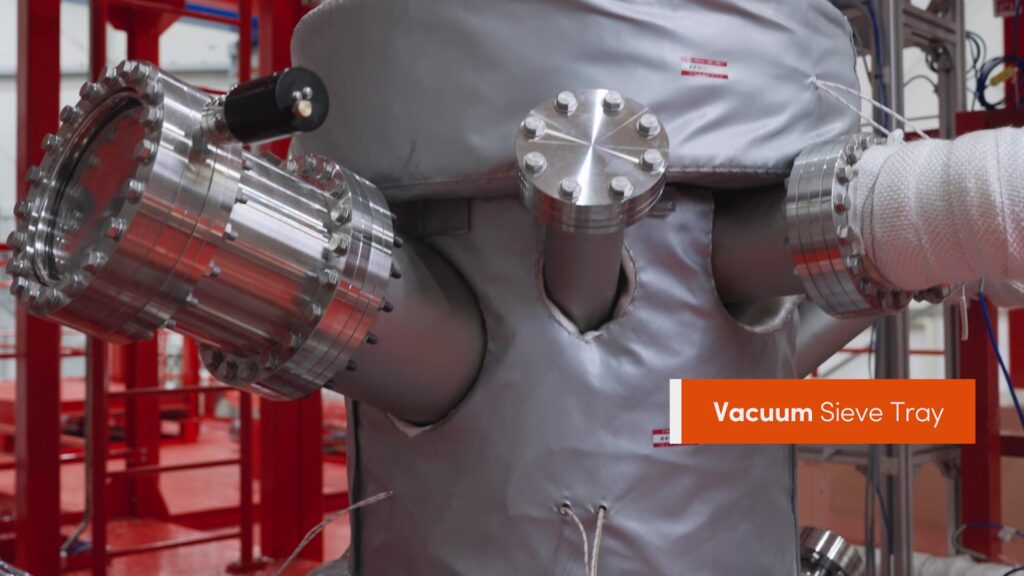

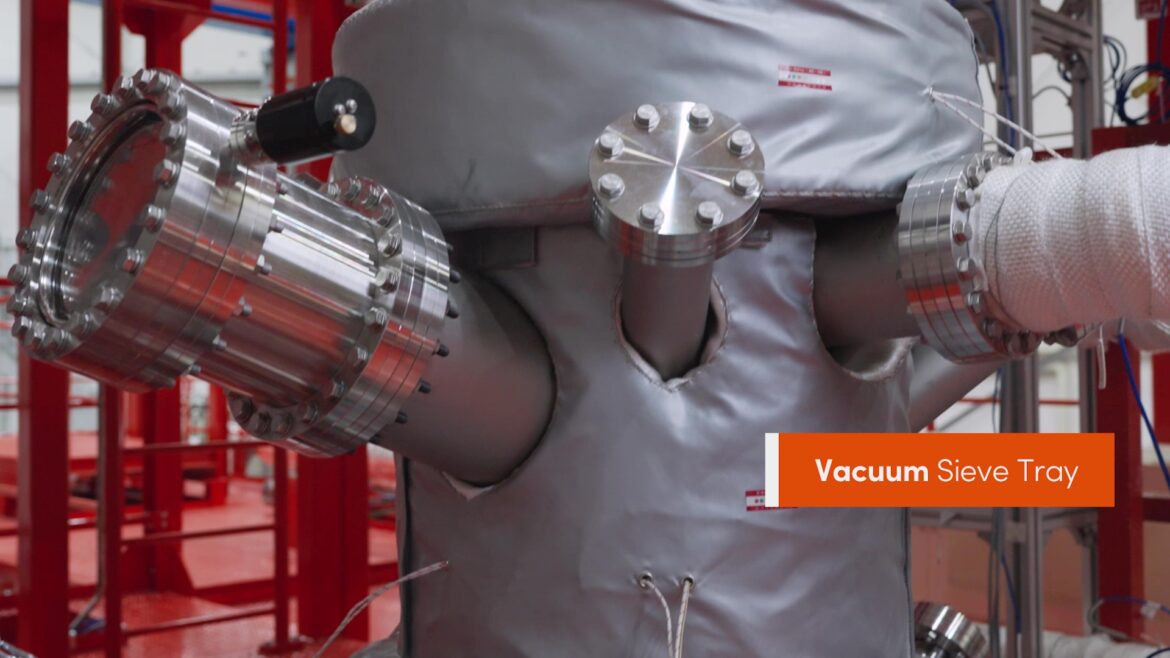

Kyoto Fusioneering, a leading innovator in fusion energy plant engineering, has begun testing hydrogen recovery from liquid metal using its proprietary Vacuum Sieve Tray (VST) technology. Conducted at UNITY-1, the company’s integrated test facility, the program aims to demonstrate the stable recovery of hydrogen – an essential step towards establishing a continuous fuel supply for commercial fusion power plants.

To achieve this, Kyoto Fusioneering is developing a Fusion Fuel Cycle System — to be demonstrated in UNITY-2 — responsible for the recovery, storage, and supply of hydrogen isotopes – tritium and deuterium – which serve as key fuels for energy-intensive fusion plants.

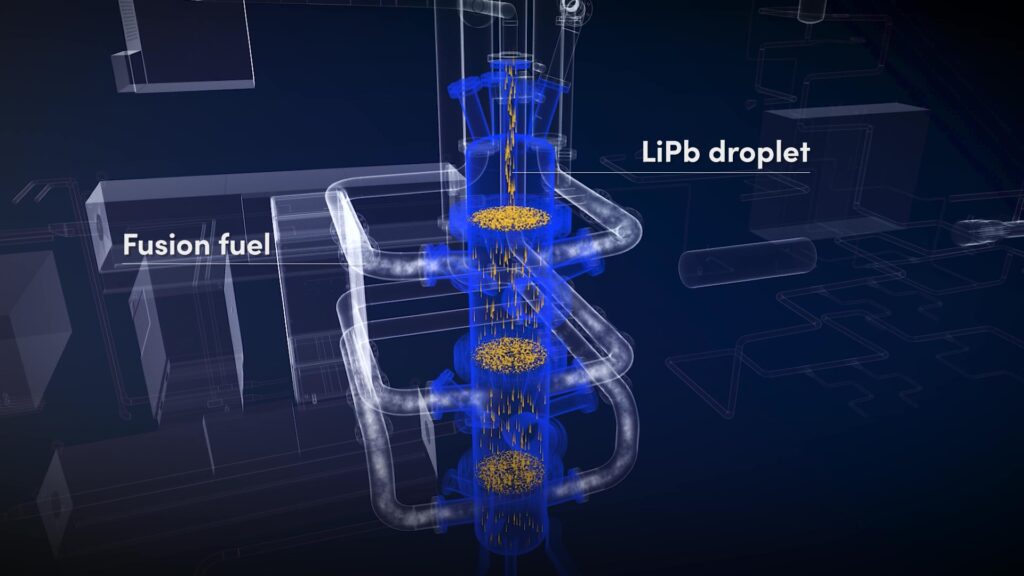

Tritium, in particular, is extremely scarce in nature and must typically be generated within fusion plants themselves. Produced by reacting neutrons contained within liquid lithium metal (lithium-lead alloy: LiPb) inside the blanket module of a fusion core, Kyoto Fusioneering’s Fusion Fuel Cycle System, to be validated through the upcoming UNITY-2 project, demonstrates the effective breeding, recovery and storage of tritium from liquid metal.

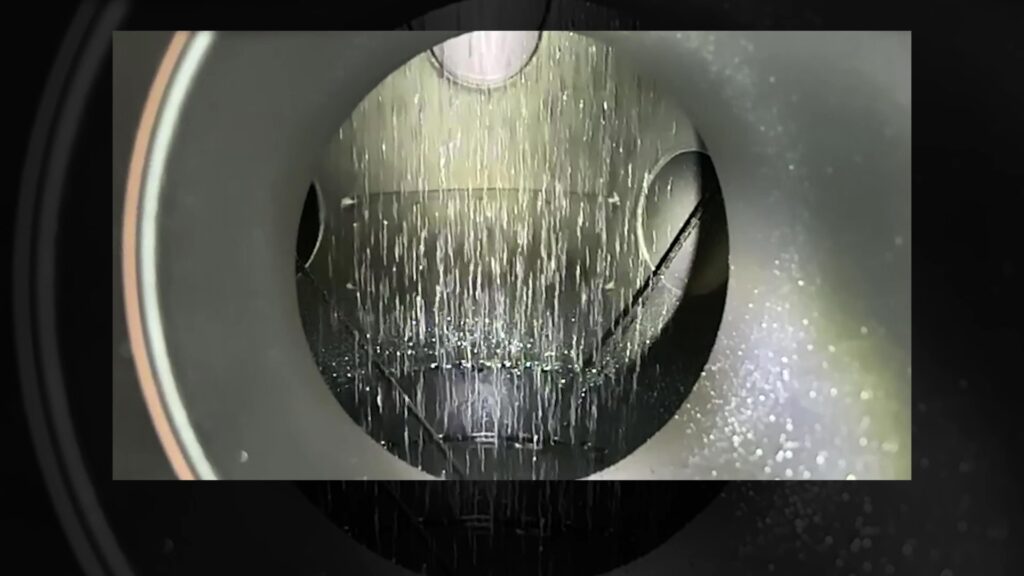

With the UNITY-1 test facility simulating the extreme heat required for fusion power generation, the embedded VST device enables the proof of principle for efficient extraction of tritium gas. To accomplish this, lithium-lead is poured into the vacuum, where it is dispersed into droplets via internal sieve trays. This process increases the surface area of lithium-lead allowing for more efficient gas-phase extraction and recovery of tritium from liquid metal.

In this initial phase of testing both deuterium and hydrogen are used as substitutes for tritium to demonstrate hydrogen recovery. The data obtained from this test will be utilized to design the VST system in UNITY-2, a project currently underway in Ontario, Canada, led by Fusion Fuel Cycles Inc., a joint venture between Kyoto Fusioneering and Canadian Nuclear Laboratories (CNL). UNITY-2 will finally validate the VST technology also when operated with tritium.

“Demonstrating the effectiveness of hydrogen recovery is a critical step towards scalable fusion power,” said Satoshi Konishi, Co-Founder & CEO at Kyoto Fusioneering. “These tests validate key components of the Fusion Fuel Cycle System, giving our industrial partners confidence in our ability to deliver reliable fuel supply in future commercial deployments.”

Image of the interior of the VST (Vacuum Sieve Tray)

Image of the interior of the VST (Vacuum Sieve Tray)

Image of liquid metal (lithium-lead) in droplet form

Image of liquid metal (lithium-lead) in droplet form

To learn more about the testing program and Kyoto Fusioneering’s UNITY-1 plant, watch the following video:

AloJapan.com