Salt and wood usually meet in a campfire, not a lab. So why are Japanese researchers using them to challenge the very idea of plastic?

Microplastics slip from laundry, tires, and packaging into bodies and oceans, dragging along a trail of health risks. In Japan, a team at the RIKEN Center for Emergent Matter Science reports a plastic built from wood’s cellulose and a common salt, choline chloride, with components already cleared by the FDA. Tuned like a recipe, the material can set hard as glass or flex into ultrathin films for packaging, and it biodegrades instead of fraying into persistent dust. Led by chemist Takuzo Aida and detailed in the Journal of the American Chemical Society, the project now turns to scaling up at a price point meant to rival petroleum-based plastics.

A new biodegradable plastic to tackle microplastics pollution

Researchers in Japan have unveiled a groundbreaking discovery: a biodegradable plastic made from an unexpected combination of cellulose and salt. Developed by the RIKEN Center for Emergent Matter Science, this material aims to address the persistent environmental problem of microplastics, those tiny, toxic fragments infiltrating ecosystems worldwide. Beyond its eco-friendly promise, this creation boasts remarkable properties that could revolutionize how we think about plastics.

Why microplastics are a growing danger

Microplastics are everywhere, released through industrial production, washing synthetic fabrics, or the breakdown of larger plastics. They spread invisibly through oceans, air, and soil, even contaminating the food we eat. Studies suggest these particles pose risks to human health, potentially affecting the heart and reproductive systems. So how do we combat a material we have become so dependent on, yet cannot afford to keep producing in its current form? An alternative that avoids creating microplastic debris is urgently needed.

The creation of cellulose-based plastic

Under the leadership of chemist Takuzo Aida, the research team developed this novel plastic by combining cellulose and choline chloride, a type of salt often used as a food additive. The process allows cellulose to become mouldable, creating a material that retains strength and flexibility. All the ingredients are FDA-approved, ensuring safety for both humans and the environment.

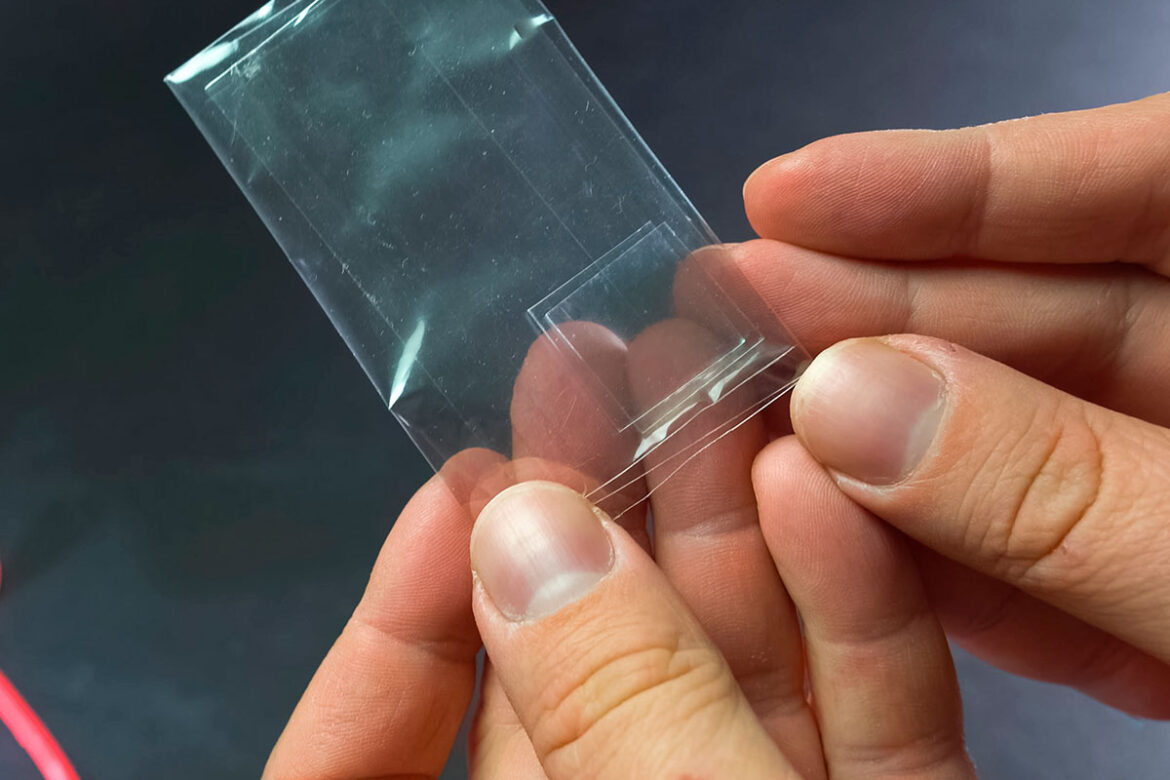

The resulting plastic can adapt to a variety of needs. It can be made as firm as glass or as elastic as rubber, making it highly versatile. Want to stretch it? This material can expand significantly without breaking. Need thin films for packaging? This plastic can deliver. It is designed to biodegrade under appropriate conditions, limiting the formation of persistent microplastic fragments.

A practical and scalable solution

One of the most promising aspects of this innovation lies in its economic feasibility. While many eco-friendly materials are expensive to produce, this plastic uses abundant, low-cost materials such as cellulose and food-grade salts, setting it apart from traditional petroleum-based plastics in terms of cost and sustainability. Large-scale production seems not only possible but practical, potentially tipping the balance toward reducing the global reliance on harmful plastics.

Takuzo Aida highlights not only the impressive technical qualities of this material but also its massive potential when implemented widely. Could this be the shift needed to protect our ecosystems and food chains from further plastic contamination?

From science lab to everyday life

This innovative plastic may soon make its way into our daily lives, from food packaging to durable everyday items. Its flexibility, lack of toxicity, and biodegradability signal a future where plastics no longer burden the environment. While challenges remain in scaling production, the possibility of replacing harmful plastics with a biodegradable competitor is an exciting step forward. What could this mean for the next chapter of material science and our planet? Time will tell.

Source : https://pubs.acs.org/doi/10.1021/jacs.5c16680

AloJapan.com