In the spring of 2025, Hiroshima quietly became the site of a technological first that may reshape Japan’s approach to infrastructure: a massive Robbins-built slurry tunnel boring machine (TBM), weighing 2,400 metric tons and spanning 13.67 meters in diameter, completed a 1.4-kilometer excavation beneath the bustling urban fabric of the city. It was deployed to construct a crucial section of the Hiroshima Expressway Line 5, a future lifeline expected to ease traffic, connect the city center to the national highway, and provide faster access to Hiroshima Airport.

Japan’s Hiroshima Expressway Line 5 is designed to improve access between Hiroshima Station and the national Sanyo Expressway via Hiroshima Expressway Line 1. Credit: Hiroshima Expressway Public Corporation

Japan’s Hiroshima Expressway Line 5 is designed to improve access between Hiroshima Station and the national Sanyo Expressway via Hiroshima Expressway Line 1. Credit: Hiroshima Expressway Public Corporation

But here’s the real headline: this was the first time in Japan’s history that such a large, foreign-made TBM was trusted to cut through native bedrock—specifically, unforgiving granitic rock with compressive strengths reaching 130 MPa. That’s roughly four times stronger than standard concrete. In a nation known for its engineering precision and homegrown tunneling methods, this collaboration with the U.S.-based Robbins Company marks a subtle but important shift toward cross-border innovation.

Digging Through Pressure, Granite, and Tradition

This wasn’t a tunnel built for show—it was a test of pressure, engineering, and patience. Operating at depths where water pressures reached up to 13 bars (with a machine capacity of 20), the TBM relied on advanced slurry technology: pressurized fluid helped stabilize the tunnel face while carrying out muck, preventing collapses in loose or water-logged soil. To handle such extreme geological conditions, Robbins outfitted the cutterhead with pressure-compensating disc cutters, capable of grinding through the abrasive, fractured granite without compromise.

But the engineering challenge wasn’t just underground. Overhead lay dense residential areas and tight urban infrastructure. To reduce risks of vibration or subsidence, the construction team drilled horizontal exploration holes every 50 meters ahead of the TBM to preemptively detect faults and adjust operations as needed.

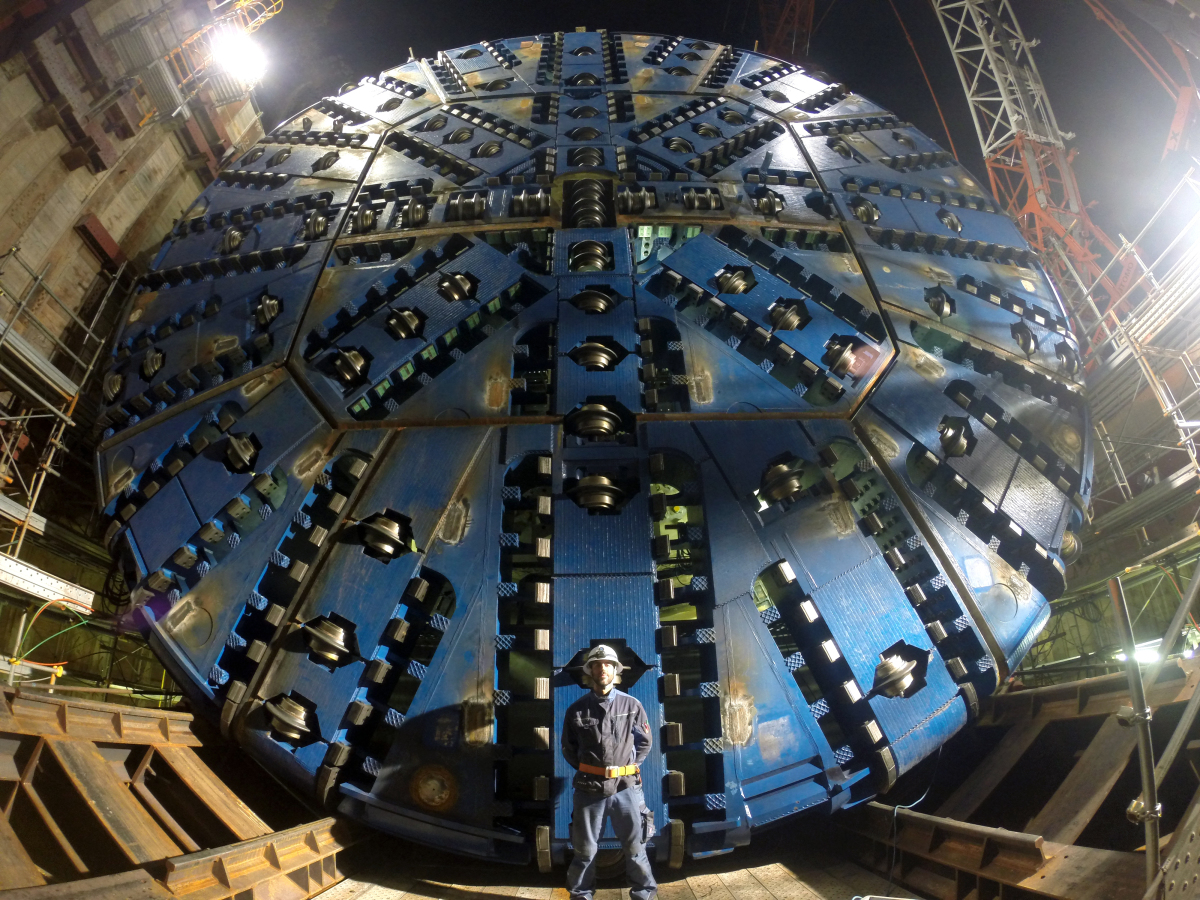

The fully assembled TBM cutterhead for the Hiroshima Expressway Line 5 tunnel excavation. Credit: Robbins

The fully assembled TBM cutterhead for the Hiroshima Expressway Line 5 tunnel excavation. Credit: Robbins

And they did it all on a postage stamp-sized site. The launch shaft sat on a 30 by 60 meter lot, meaning the 2,400-ton machine couldn’t simply roll in—it had to be shipped in parts and assembled on-site using Robbins’ proprietary Onsite First Time Assembly (OFTA) method. The whole operation, from launch to breakthrough, took just eight months.

A Quiet Breakthrough That Speaks Volumes

On April 30, 2025, the TBM broke through its final stretch—marking a symbolic as much as a technical success. Engineers, contractors, and municipal leaders quietly celebrated, but their statements carried the weight of something more.

Tetsuya Taniguchi, Deputy Director at Japanese contractor Obayashi, put it plainly: “There are very few precedents for large-diameter tunneling in hard rock using slurry TBMs in Japan. Robbins’ disc cutter experience was excellent, and this project gave us valuable results and knowledge.”

Meanwhile, Shinichi Konda, chief engineer at Robbins, struck a hopeful tone: “We are proud of this tunnel being completed for the city of Hiroshima. From the complex machine launch to breakthrough, this project will have a huge positive impact.”

When completed—likely in 2027—this tunnel won’t just be a line on a map. It will be a lifeline. An invisible conduit beneath the streets, seamlessly connecting commuters and commerce across a city already brimming with memory and momentum.

AloJapan.com