One of the interesting things about my job is that I get to talk to engineers and product planners and designers and other Important People in the car industry. And, after well over a decade of carefully crafting a persona that many people would call, perhaps derisively, an “idiot” or more charitably, a “drooling simpleton,” I’m often in a place where I can offer suggestions or ideas to these sorts of people, and they’re very often surprisingly willing to listen to me, or at least pretend to.

One of the ideas that I can’t get out of my head and have brought up to these sorts of people on numerous occasions is the concept of battery swapping for electric vehicles. And, incredibly, at least to me, every single Important Person I have spoken with in the EV industry has told me, in pretty clear, straightforward terms, that battery swapping is a Bad Idea.

![]()

![]()

That may be why I was happy to see that Mitsubishi Fuso is planning a battery-swapping program in Japan, specifically for its line of eCanter commercial trucks. The swapping program is being done in conjunction with Ample, an American-based company that seems focused on modular batteries and battery swapping – two ideas that I have been championing for years.

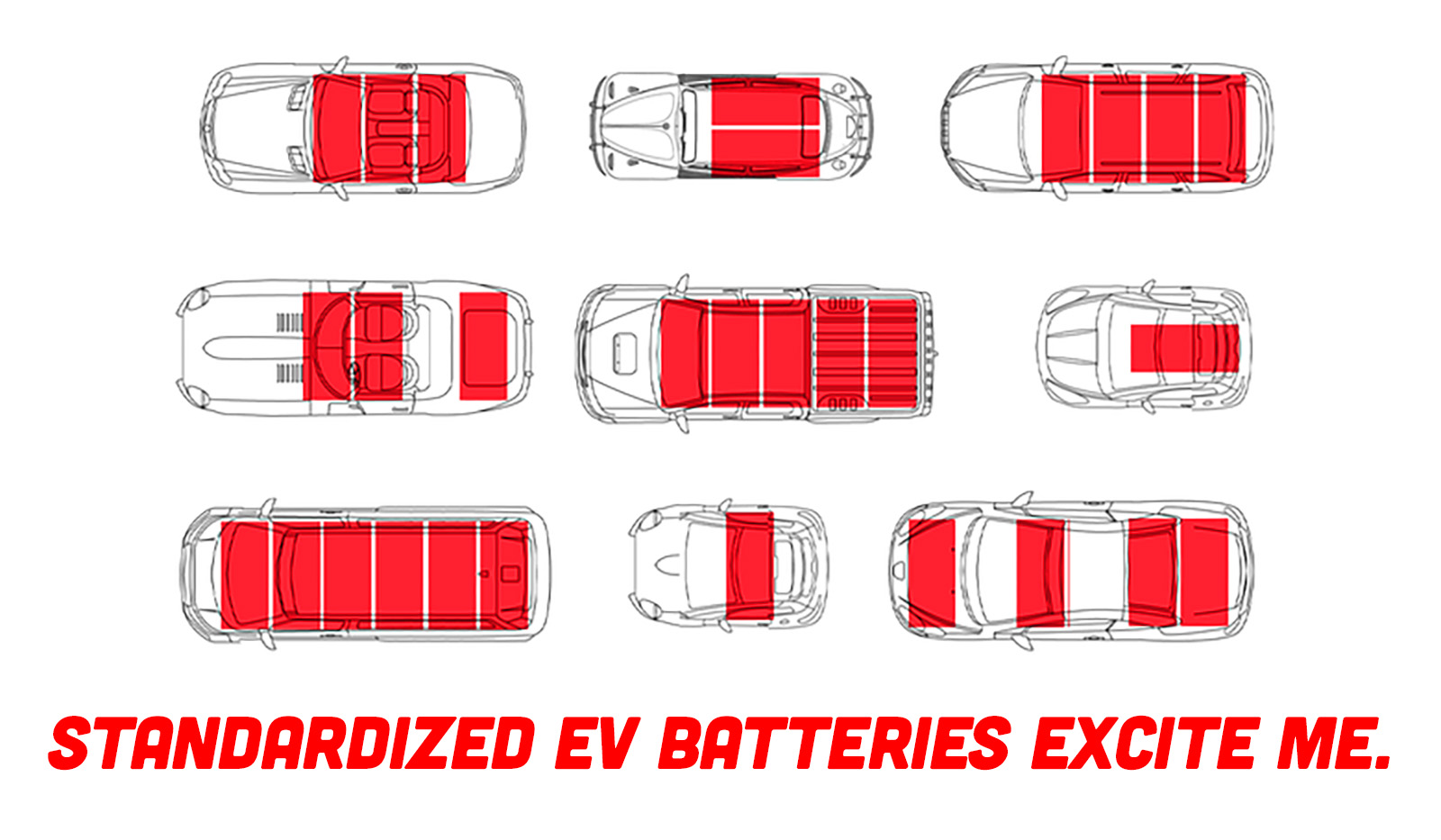

Illustration: Jason Torchinsky

Illustration: Jason Torchinsky

I really love this approach; I’ve never really been thrilled with the idea of actually owning a battery in an EV– why do I want to have a major structural part of my car be something that is 1. Rapidly becoming outdated tue to developments and 2. Arguably a consumable, even if they do last a nice long while – and I’ve always thought that standardizing battery sizes and connectors could lead to more competition and commoditization of batteries that would lead to less cost to consumers, and that’s whose side I’m on, anyway.

Ample does seem to have this approach, at least based on what I saw on their website. Their partnership with Mitubishi Fuso is focused on the last-mile, in-city trucking and delivering market, and uses the Mistubishi eCanter truck as the platform. These trucks, introduced in 2023, have driving ranges between 62 and 200 miles or so, and EV light-duty trucks like these can take between a few hours and up to 10 hours to recharge using conventional means.

This battery swapping plan would reduce that time to minutes, five minutes if this diagram proves to be prophetic:

Image: Mitsubishi-Fuso/Ample

Image: Mitsubishi-Fuso/Ample

Oh, one quick aside about the eCanter; on Mitsubishi-Fuso’s site for the eCanter, the company has a funny way of naming its wheelbase options. Look at this:

Screenshot: Mitsubishi-Fuso

Screenshot: Mitsubishi-Fuso

So we have Short, Long, and Extra Super Long! That last one feels just a little too exuberant, but I like it. They could have done Extra or Super, but someone there was feeling it enough to say screw it, we’re doing both. Extra Super, mothertruckers!

Okay, back to the battery swapping plan. It seems the battery swapping stations will be built according to Ample’s current designs, and the trucks will be adapted to be compatible with Ample’s modular batteries, with a trial on public roads scheduled for this winter.

Image: Mitsubishi-Fuso/Ample

Image: Mitsubishi-Fuso/Ample

I’m excited by this, but also reminded of what all these CEOs and CTOs and engineers have told me over the years: if you tightly integrate a custom battery pack into an EV, everything can be lighter and more efficient; they’re worried about connector life with all the cycles of fluid/electric connection and disconnection; and they just all seem to be down on the ideas of standardizing altogether. But why?

I think while they have valid points – connector life is an issue, of course, and yes, you can design a more efficient overall vehicle with a custom, highly integrated battery pack – a lot of the resistance may come down to a certain sort of pervasive engineering hubris. Everyone thinks they can do it a little better than everyone else, and while they may all be right, maybe it just doesn’t really matter all that much.

Maybe people would rather have EVs that don’t become unsellable paperweights over time in rare and outdated in probably most cases, or would rather adjust how much battery they haul around based on their dynamically-changing needs [Ed Note: The weight change would alter the vehicle’s dynamics, which opens up a whole new can of worms. -DT], or have more options for battery replacement instead of a slightly more efficient, integrated battery design.

I think a last-mile delivery truck platform like these eCanters is an ideal test case for this sort of modular, swappable battery, because it’s a platform that would never really need structural batteries in the first place. Why not make them swappable, especially if the batteries are just big boxes slung between frame rails?

Maybe all those CTOs and engineers and everyone else are right, and I’m a big, sloppy moron with a lot of bad ideas. Fine. I’ve accepted that. But is Mitsubishi-Fuso an idiot, too? Or is it possible there’s some merit to the idea of standardized and swappable batteries? I guess we’ll see how it goes, and then I’ll just wait for all those bigshots in the EV world to send me apologetic fruit baskets. I’ll hold my breath.

AloJapan.com